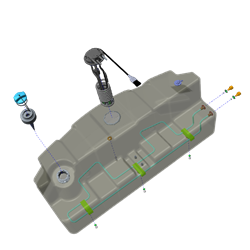

"...some of the most well thought-out fuel tank designs we have ever manufactured"

-Account Manager, Rotomolding Manufacturer

WOMBAT Labs has extensive experience developing rotomolded parts. We can take your design ideas from concept to production, optimizing them for the rotomolding process. Working side-by-side with our established tooling and molding partners, or with your existing vendors, we will ensure that your form, fit, function, and manufacturability objectives are met.

Rotational Molding, or Rotomolding, is a manufacturing process using a hollow multi-piece mold, heat, and biaxial rotation. As the mold is heated and rotated, the composite material placed inside of it coats the internal surfaces. Once all of the material has been evenly distributed, the mold is cooled, then the finished one-piece part is removed for post-mold processing.

Products commonly produced using Rotomolding:

- Fuel tanks

- DEF tanks

- Air induction system components

- Sprayer tanks

- Seed hoppers

- Combine corn head snouts

- Seats/furniture

- HVAC ducts

- Cab components

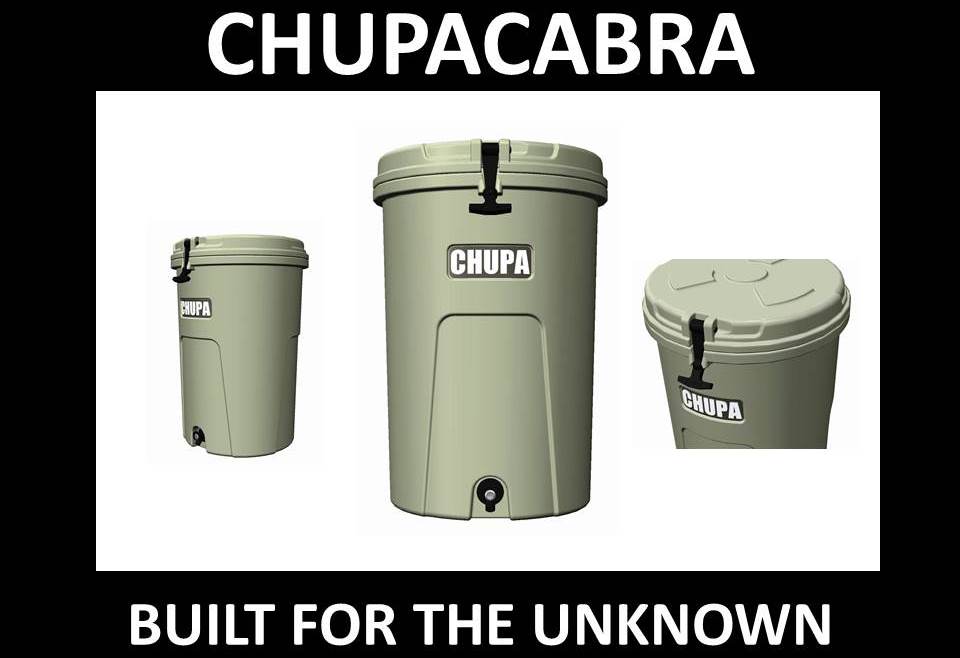

- Numerous consumer products (boats, coolers, etc.)

Have a challenge that we can help you with? Send us a few project details and we'll get started on a quote right away.